Concrete is a complex system, and research on various raw materials has never been interrupted. Every point can be discussed in an article, and after each update, it seems that this can also be written. Then I realized that if I continued like this, I really didn't know how long my field of additives would be delayed. Today, let's jump directly to the synthesis of polycarboxylate additives. As for the exploration of the performance of other raw materials in concrete, let's talk about it wherever we think in the future.

When I first entered the industry, I had two books. One was the Handbook of Concrete Additive Formula, and the other was about the synthesis of polycarboxylates. I forgot the name. When I first entered the industry, I bought it. At that time, my mood was like a treasure trove, thinking that I relied on it for promotion and salary increase. However, the more I read, the cooler my heart becomes. The articles in the book introduce various complex synthesis pathways. Perhaps when I entered the industry, I happened to enter the year of replacing the old with the new in the synthesis process of polycarboxylic acid. There are many differences between the processes and practical applications introduced in this book. At this time of stagnation, the old craftsmanship has no practical value, while the new craftsmanship appears mysterious and mysterious. Even now, aside from these outdated books, most of the recently updated literature on the synthesis of admixtures has been introduced vaguely. This ratio is not indicated, and that step is ignored. The author believes that there is no need to be so secretive about some basic and mature processes. Below, I will record in detail the process of a synthesis experiment. For readers who have mastered synthesis technology, this formula is not novel or even a bit outdated, but it is better than reality. The synthesized mother liquor also possesses the same performance as most products on the market. Readers who are interested in new industries can follow this step to perform a synthesis.

1、 Equipment and instruments

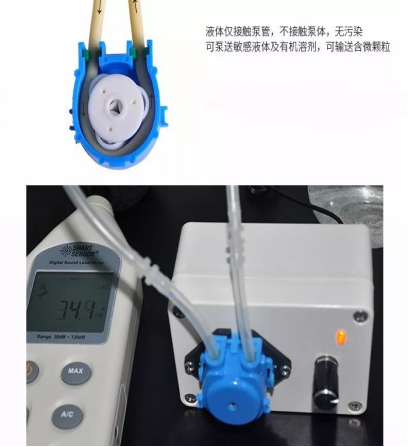

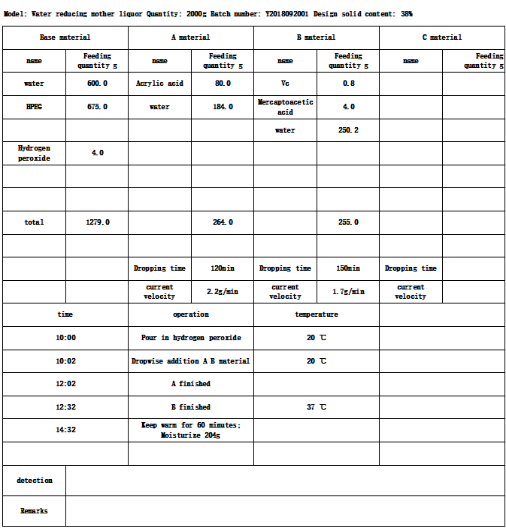

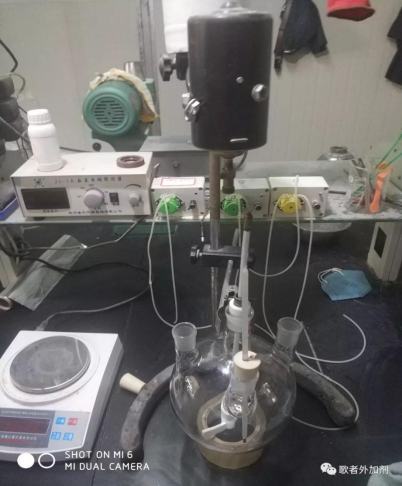

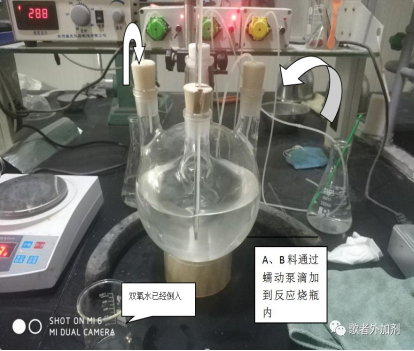

The equipment required for synthesizing polycarboxylate admixtures at room temperature is not complicated, and the core is the peristaltic pump. The author has used a hanging bottle for drip addition operation, although it is simple, the product can still be obtained. A good peristaltic pump has a market price of around 2000 yuan per unit, while the double drip process only requires a peristaltic pump for 4000 yuan, as shown in Figure 1. However, the author prefers to use another relatively inexpensive peristaltic pump. Although the operation is relatively complicated, it is cost-effective at 100 yuan per unit, as shown in Figure 2. The working principle of the two peristaltic pumps is the same. This peristaltic pump is very simple with only one switch that can adjust the speed. In terms of pipelines, the smallest diameter needs to be selected, and the flow rate is not easy to adjust. After purchasing, set the flow rate switch of the peristaltic pump to the minimum gear, and then use a stopwatch and electronic balance to calculate the flow rate of this peristaltic pump. In the future, this flow rate can be kept constant by increasing or decreasing the water consumption in the drip addition beaker to ensure the smooth completion of the drip addition process. For example, the measured flow rate of A peristaltic pump is 2.2g/min, and the material in the beaker needs to be dropped and added within 120 minutes. So the total weight of the material in the A-drop beaker is 2.2g/min * 120min=264g. By using this simple peristaltic pump, the cost of equipment can be greatly reduced. It seems that this cheap peristaltic pump is only available for sale on Taobao. It seems that there is not much demand in this market. Of course, friends who have mines at home can choose freely.

Figure 1

Figure 2

1.2 Agitator power 160W. The agitator blade can be selected with a longer blade length as needed. A universal Taobao search is sufficient.

1.3 Four necked flasks with a capacity of 2000ml are sufficient for use. The reason for choosing a four necked bottle is that some synthesis processes involve double drop addition. The source is also omnipotent Taobao.

1.4 Other commonly used equipment such as beakers, glass rods, and electronic scales will not be introduced in detail.

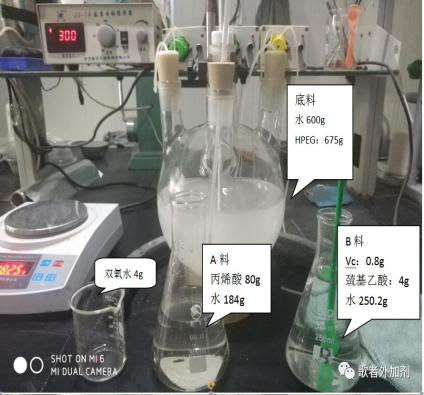

2、 Raw materials

2.1 The current synthesis process of water is mainly based on tap water, and there are few reports that the water quality from a certain region affects the performance of the mother liquor.

2.2 The abbreviation HPEG, also known as methylallyl polyoxyethylene ether, is the main raw material for synthesizing mother liquor. The full name is too long, and almost no one will use it in communication. Every time I want to write my full name, I have to search for its name. The manufacturer of this synthesis application is Fujian Zhongshan Chemical Co., Ltd. (please see the sponsorship fee provided by the leaders of Zhongshan Chemical).

2.3 Acrylic acid manufacturer Shandong Wanhua Chemical. Recently, the author's Wanhua Chemical stock has fallen by 20%, which is truly heartbreaking. But the product that should be used still needs to be used.

2.4 Vitamin C, also known as anti sepsis acid or Vc, is described in literature as having both oxidizing and reducing properties. The synthesis of mother liquor utilizes its reducing function. The manufacturer is Shiyao Group, and the world's largest production capacity manufacturer of Vc is Shiyao Group. It is said that the production process of vitamin C in China is ahead of foreign countries.

2.5 Hydrogen peroxide, also known as hydrogen peroxide. Concentration 27.5%; This year, the country has defined hydrogen peroxide as a raw material for easy to produce explosives, and the control measures are relatively strict. In some areas, purchasing hydrogen peroxide requires filing with the public security bureau, and even purchasing a small bottle requires filing. Hydrogen peroxide is an oxidation-reduction system formed by the combined action of oxidants and Vc, with the aim of reducing the chemical energy of the reaction between large monomers and acrylic acid. This is the main reason why synthesis can be carried out at room temperature.

2.6 Mercaptoacetic acid acts as a chain transfer agent. Without a chain transfer agent, the molecular weight of the synthesized product will be too large and will not have optimal performance. The author once conducted a synthesis experiment without adding mercaptoacetic acid, and the resulting product had a very high viscosity (molecular weight) that could be used for Spring Festival couplets. Generally imported ones are used, with small quantities and higher prices.

3、 Operation

Writing and discovering that there is really no content in the operation is actually the simplest thing. The following image is an experimental record sheet that I used. Weigh the materials according to their respective weights in the table. Let HPEG dissolve in water for about half an hour. Pour hydrogen peroxide into a four necked bottle and stir for 2 minutes while turning on peristaltic pumps A and B. Ensure that A drops are added for 120 minutes and completed; B drops for 150 minutes are complete. After dripping, continue stirring for one hour; Just add water and adjust the solid content of the mother liquor. The workbench is a bit messy, I will pay attention to aesthetic treatment when taking photos in the future...

Synthesis is an exothermic reaction, and as the addition progresses, the temperature of the substrate will continue to rise. The fixed ratio and the rising temperature of the raw material synthesis are the same, that is, the exothermic temperature is the same. If the temperature rise is abnormal, it indicates that there is a problem with the synthesis reaction. Another thing to note is that the drip time for synthesizing 1000g, 2000g, or for mass production of 10 tons is fixed.

After adding water, a synthesis test is also completed. The synthesis experiment operation is not complicated, and it can be said that this reaction is really a very simple process in chemical production. It is worth studying what effects different raw materials or processes will bring to the application.