The purpose of concrete adaptation and admixture adaptation is to adjust the state of concrete to have good working performance. In short, the good condition of concrete is that it has good fluidity within 1-2 hours and all kinds of raw materials are seamlessly integrated, without any stone separation or water leakage.

The adaptation of concrete admixtures is often carried out with a mix ratio of C30. Common C30 combinations, such as Table 1. Currently, various mixing plants are optimizing the amount of rubber materials used. The actual amount of adhesive used is less than 380kg/m ³, For example, 350-370kg/m ³.

Cement | Mineral powder | FLY ash | Sands | Shizi | Water consumption | Additive dosage | |

Unit (g/l) | 220 | 80 | 80 | 800 | 1050 | 170 | 2.00% |

10liters | 2.2kg | 0.8kg | 0.8kg | 8kg | 10.5kg | 0.17kg | 76g |

The more materials are weighed each time, the more the concrete's adaptability performance is in line with actual production. Just too much weighing actually increases the workload of the staff. Most of the concrete in each batch consists of 10-25 liters. Readers who have just been exposed to additives are confused about how to calculate the dosage of additives. The dosage of admixtures=dosage of admixtures/dosage of adhesive * 100%, for example, the dosage of admixtures in one liter of concrete in the above table is (220g+80g+80g) * 0.02=7.6g. Generally, a 10 liter adapter is used, with an additional dosage of (220g+80g+80g) * 0.02 * 10=76g.

Pour all the raw materials into the mixing pot one by one, then turn on the mixer and add water and additives while stirring. Finally, the remaining admixtures and water (10% -20%) should be added appropriately after observing whether the concrete has reached saturation level.

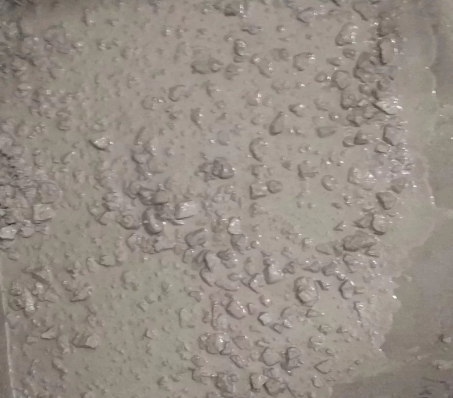

The first batch of concrete adaptation will have significant experimental errors. The mixing blade inside the mixer will form large gaps with the inner wall due to long-term wear and tear, causing the concrete slurry to remain on the inner wall. The poured concrete lacks some slurry, making the observation objective. The solution is simple and crude - after roughly observing the first batch of concrete, simply discard it and proceed with the second batch adaptation (as shown in Figure 1).

Figure 1: Concrete state inside the pot

If you feel that the state of the concrete meets the requirements, you can take it out of the pot (as shown in Figure 2). At this point, it is necessary to measure the "slump" and "expansion" of the concrete as required. The general requirement is for the initial concrete slump to be 200-210mm and the expansion to be 540-580mm.

Figure 2 :Inverted state

After meeting the initial requirements for concrete, we also need to observe the "time loss" of concrete, abbreviated as loss. The smaller the time loss, the better the workability of concrete (as shown in Figure 3). After time loss, the flow rate, slump, and expansion of concrete all decrease. The time and requirements for economic losses vary in each region.

Figure 3: Concrete state after one hour

There is only one good state of concrete, and there are indeed millions of bad ones.

1.The initial flow rate of concrete is slow and the slump is small. We need to increase the amount of water reducing mother liquor to solve the problem.

2.The concrete has poor slump retention effect. It is necessary to increase or change the types of retarders and increase the amount of slump retention mother liquor to solve the problem.

3.Concrete is prone to bleeding and bleeding; Pulp weight; Slight exposure of stones. Need to add air entraining agent to solve the problem.

4.Poor cohesion of concrete. We need to add water retaining agents to solve the problem.

5.Concrete loses a lot through pumping. Firstly, consider changing the type of air entraining agent.

Various issues are intertwined and require technical personnel to analyze them one by one through their own experience. In recent years, cement manufacturers have used a variety of admixtures to reduce costs. Due to the extremely tight environmental management, the sand in different sand fields varies greatly. Polycarboxylic acid additives do have sensitive properties when they possess various excellent properties. The changes in various raw materials of concrete result in changes in the state of the concrete, and the formula of admixtures needs to be updated in a timely manner. It can be said that the current application of concrete admixtures relies on three parts adaptation and seven parts tracking. If the changes in concrete raw materials can be accurately grasped, the adaptability of admixtures can also have clear directionality.

PS: The following figures show the concrete state with certain issues.

Excessive dosage of additives.

Poor liquidity and low dosage of additives

Minor overdose of additives, exposing stones.

After one hour, the concrete loses a lot of time.